Date: 02-APRIL-2012 Last Updated: 9-FEBRUARY-2026

White Film on LC–MS Source with Very Low Background Noise: Is the Diamond Hydride column bleeding?

Short Answer: Unlikely. Cogent TYPE‑C™ columns (including Diamond Hydride™) are engineered with direct Si–C bonds and show very low bleed, even in LC–MS.

A persistent white film on the ion source almost always indicates mobile‑phase additive or buffer residue accumulating over time—not stationary‑phase bleed. Use the lowest effective additive concentration, optimize your method for ANP on TYPE‑C, and follow a regular source‑cleaning schedule.

What You’re Seeing—and Why It Happens

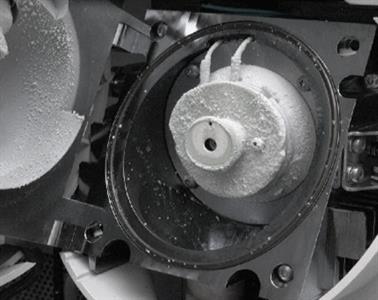

- Observation: White/opaque film building on the LC–MS source or inlet optics while overall background noise remains low.

- Primary cause: Non‑volatile or semi‑volatile additives (e.g., ammonium salts) and/or sample matrix components drying on hot source surfaces. Over many injections, these deposit as films even when chromatographic background is minimal.

- Why it’s not column bleed: TYPE‑C phases (e.g., Diamond Hydride™) are chemically robust and exhibit minimal bleed under LC–MS conditions; operator reports of white film correlate with additive loading, not stationary‑phase loss.

Method & Additive Practices That Prevent (or Worsen) Films

Use the lowest effective additive concentration

-

For sensitivity in negative‑ion mode, ammonium formate/acetate are common but reduce MS response at higher levels; keep concentrations as low as your assay allows to minimize residue and ion suppression.

Prefer volatile acids when possible

-

Where chemistry allows, 0.1% formic or 0.2% acetic acid can substitute for high salt, improving ESI cleanup and reducing deposits (especially in positive ion). Validate that analytes ionize adequately without buffers.

Mind ionic strength and ANP behavior

-

In Aqueous Normal Phase (ANP) on TYPE‑C, ionic strength has a smaller effect on retention than in HILIC—so you can often back off additive levels without sacrificing retention, reducing the risk of salt films in the source.

Align injection solvent and gradient

-

Mismatched diluents (e.g., MeOH‑rich vs. ANP start conditions) can distort peaks and encourage matrix drop‑out early in the run; match the diluent to initial mobile phase to minimize unintended precipitation. (General best practice derived from ANP guidance and MS maintenance literature.)

Field/Maintenance Tech Checklist

1) Verify the column is not at fault

- Check pressure stability and baseline; TYPE‑C columns show low bleed and stable backgrounds. If background noise is low while deposits increase, suspect additives/matrix, not column bleed.

2) Inspect the source routinely

- Weekly (high‑throughput) or biweekly (moderate): remove the spray shield/cone/inlet lens and inspect for salt haze or crystalline film. Record photos in the service log. Clean per platform SOP.

3) Clean with the right sequence

- Follow OEM SOP (e.g., water → MeOH → IPA or as specified), then re‑tune. Avoid abrasives; swap gaskets/O‑rings if etched or swollen. Validate signal recovery on a standard mix post‑clean.

4) Reduce additive load at the source

- Dilute buffers if peak shape and ionization permit. If negative mode demands salt, keep A/B concentrations symmetrical and as low as workable (e.g., ≤5–10 mM starting point). Document the lowest validated level in the method file.

5) Schedule preventive rinses

- Add a brief high‑organic or water/organic rinse segment at the end of each batch to clear late‑eluting matrix. This limits residue carryover into the next sequence and slows film growth.

Troubleshooting Flow (When Film Appears)

-

Confirm background is still low; if yes, suspect additive film, not bleed.

-

Clean source components; re‑establish baseline sensitivity with a standard.

-

Lower additive concentration (formate/acetate) or switch to volatile acid where possible; re‑validate peak shapes and LOQs.

-

Tweak ANP gradient and diluent match to avoid early precipitation.

-

Set maintenance cadence (e.g., every 500–1,000 injections or sooner for high‑salt methods).

Field Check for “White Residue” (Quick MS‑User Test)

If you suspect the white material is silica residue, a simple bench test can help rule it out:

- Wipe the suspected source using a water‑soaked Kimwipe.

- Rinse that wipe into a clean beaker with additional water.

-

Observe the particulates: if the white particulates dissolve, they are not silica (silica will not dissolve in water under normal conditions).

This quick check is particularly useful at the LC–MS interface or during post‑run cleanup: dissolving residue typically points to buffer salts (e.g., acetate/formate/phosphate), matrix precipitates, or mobile‑phase additives—not to stationary phase shedding.

When to Suspect True Column Problems Instead

-

Rapid pressure rise, baseline drift, or loss of efficiency that persists after source cleaning may indicate frit contamination or bed issues. Consider reverse‑flush cleaning per column guidance before replacement.

Key Takeaways

-

White film + low background ≠ column bleed; it’s additive residue. Keep buffers minimal, clean routinely, and leverage ANP characteristics of TYPE‑C to reduce ionic strength without losing retention.

References:

- Chrom Resource Center Tip: Choose a Suitable Mobile Phase Additive for Negative Ionization Mode in LCMS (salt levels vs sensitivity).

- Chrom Resource Center Tip: The effect of ionic strength of the mobile phase additive in ANP (ANP less sensitive than HILIC; lower additive is feasible).

- OEM/Platform Guidance (general): LC–MS maintenance and method robustness practices.